IN THE NEWS

Arrow Fabricare Celebrates 100 Years of Cleaning Clothes

DECEMBER 12TH, 2014 - KANSAS CITY STAR

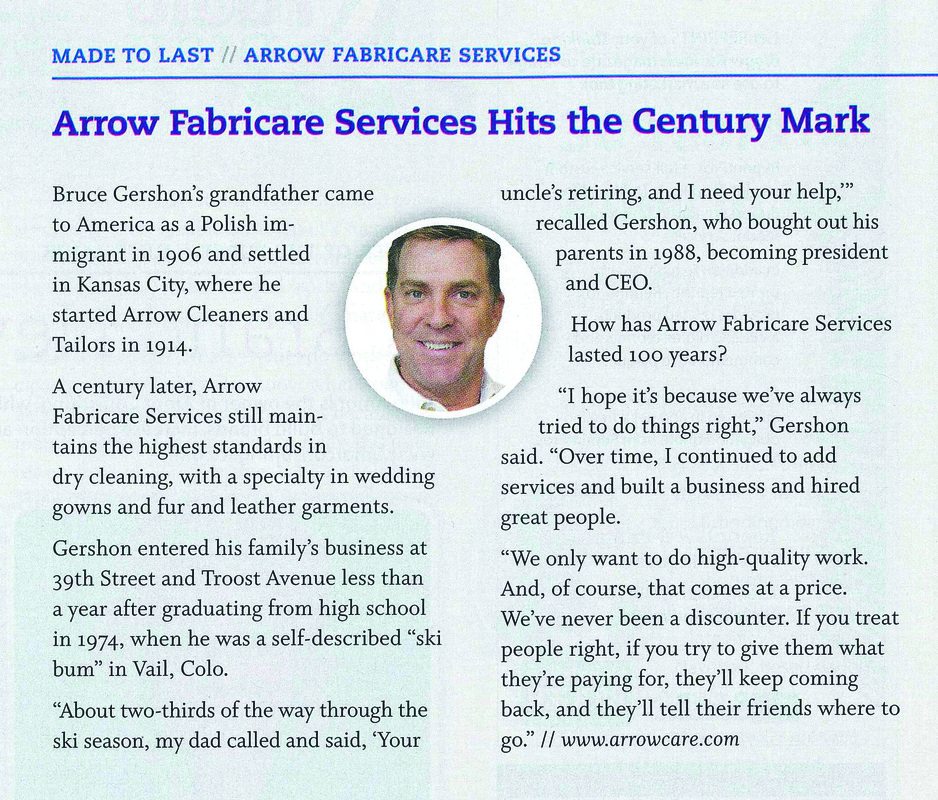

Arrow Fabricare Services Hits the Century Mark

Arrow Fabricare Services Turns 100

|

November/December 2014 - American Drycleaner

Click to download whole story

| |||||||

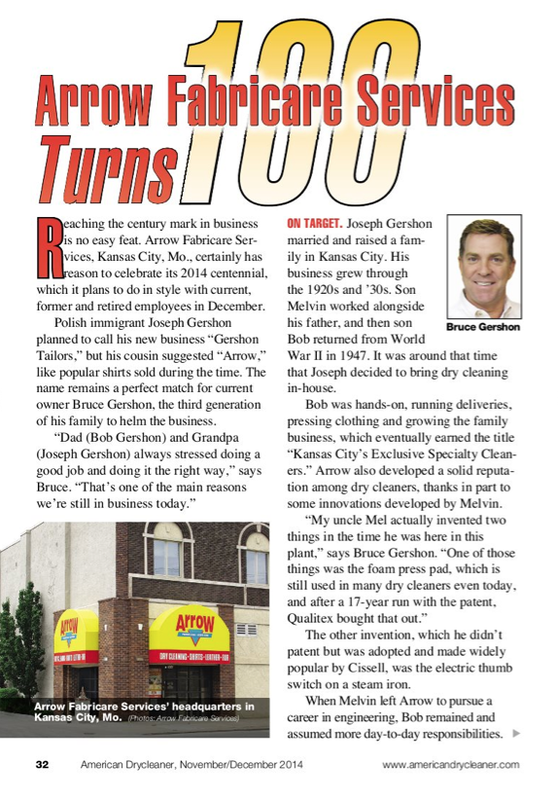

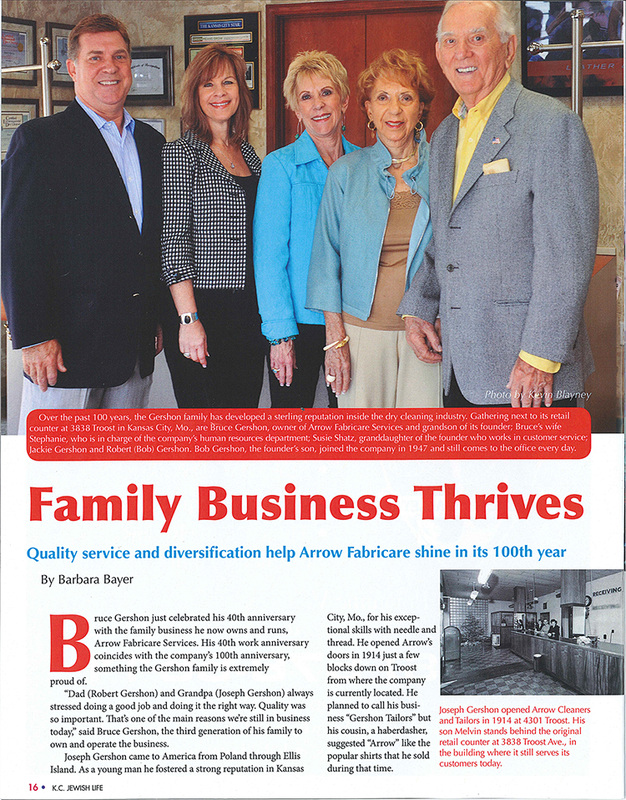

Family Business Thrives

|

October 2014 - KC Jewish Life Magazine

Click below to download whole story

| |||||||

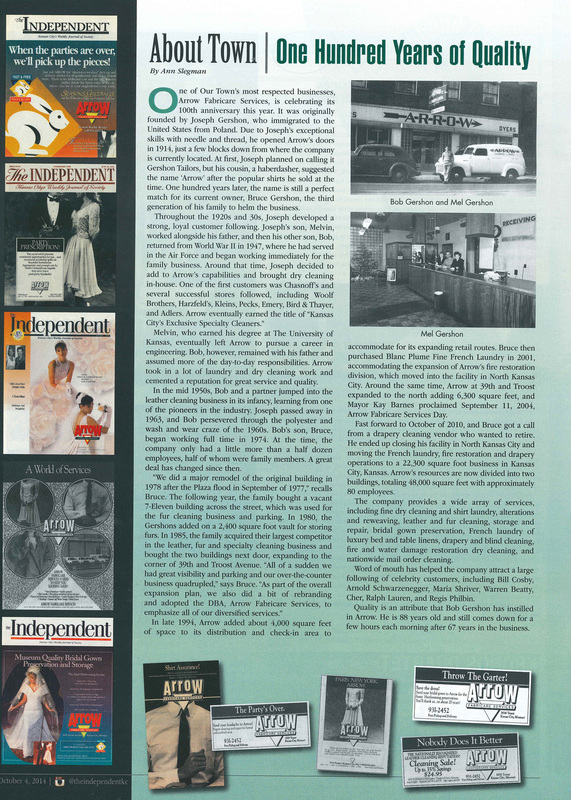

About Town - One Hundred Years of Quality

|

October 2014 - The Independent article

Click below to view online article http://www.kcindependent.com/arrow-fabricare/ |

100 years later, the dream lives

|

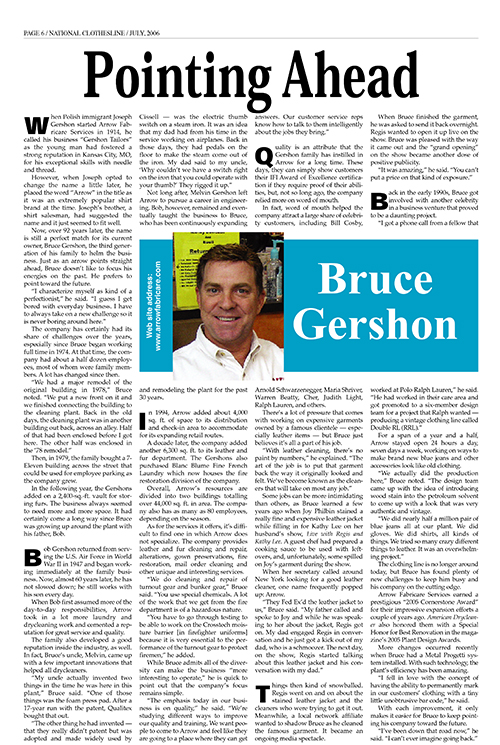

September 2014 - National Clothesline Article

Click below to view article |

Carnival Ball Prep: Where to get your gloves cleaned

By Sue Strachan, NOLA.com | The Times-Picayune

Email the author | Follow on Twitter

on August 19, 2014 at 9:57 AM, updated December 02, 2014 at 12:57 PM

A season of Carnival balls and presentations can take a pristine pair of white, kid-leather gloves and make them look like they were found on Bourbon Street. Cocktails, food, pens, lipstick, foundation, eyeliner -- anything that can possibly mark, stain and soil your gloves -- will do so.

Mine -- opera-length, white, kid-leather -- by the end of the season needed a bit of refreshing. I was tempted to try the many homegrown tips I read on the Internet. (Gently run lighter fluid on surface dirt was one recommendation.) Instead, I asked around for places to have them cleaned.

Though everyone I spoke to highly recommended getting the gloves professionally cleaned, no one could point me toward a local establishment. (Many recalled a former dry cleaner that is now closed.)

I checked out who Florentine Gloves used – Arrow Leathercare in Kansas City, Mo. This company not only revitalizes post-Carnival gloves – and most things made out of suede and leather – it also cleans bridal gowns, debutante dresses, UGG boots, fur, bedding, rugs and more.

I sent my pair off for an estimate, and a few days later they called to say it would cost $45 to clean (my bill says "heavy stain"), which I thought was fair. Prices will vary due to size of gloves and how soiled they are. (It also did not include the cost of shipping.)

"White leather is the hardest to clean," said Bob Gershon of Arrow Leathercare. Founded by Gershon's father, a tailor, in 1914, Gershon expanded it to dry cleaning after he returned from World War II. Today, Arrow Leathercare is still family-owned and operated -- his son owns the company, and his daughter works there, as does Gershon, who still goes to the office at age 88.

About stains, Gershon says, "Many times you don't know what the stain is, except for ink. (Unfortunately, the harder we work on it, the color of the leather may change." And, he told me, if the stain turns yellow, those gloves will need to be refinished.

Fortunately, I sent my gloves there before any yellow stains could occur, so for upcoming Carnival season my gloves are now in tip-top shape.

Email the author | Follow on Twitter

on August 19, 2014 at 9:57 AM, updated December 02, 2014 at 12:57 PM

A season of Carnival balls and presentations can take a pristine pair of white, kid-leather gloves and make them look like they were found on Bourbon Street. Cocktails, food, pens, lipstick, foundation, eyeliner -- anything that can possibly mark, stain and soil your gloves -- will do so.

Mine -- opera-length, white, kid-leather -- by the end of the season needed a bit of refreshing. I was tempted to try the many homegrown tips I read on the Internet. (Gently run lighter fluid on surface dirt was one recommendation.) Instead, I asked around for places to have them cleaned.

Though everyone I spoke to highly recommended getting the gloves professionally cleaned, no one could point me toward a local establishment. (Many recalled a former dry cleaner that is now closed.)

I checked out who Florentine Gloves used – Arrow Leathercare in Kansas City, Mo. This company not only revitalizes post-Carnival gloves – and most things made out of suede and leather – it also cleans bridal gowns, debutante dresses, UGG boots, fur, bedding, rugs and more.

I sent my pair off for an estimate, and a few days later they called to say it would cost $45 to clean (my bill says "heavy stain"), which I thought was fair. Prices will vary due to size of gloves and how soiled they are. (It also did not include the cost of shipping.)

"White leather is the hardest to clean," said Bob Gershon of Arrow Leathercare. Founded by Gershon's father, a tailor, in 1914, Gershon expanded it to dry cleaning after he returned from World War II. Today, Arrow Leathercare is still family-owned and operated -- his son owns the company, and his daughter works there, as does Gershon, who still goes to the office at age 88.

About stains, Gershon says, "Many times you don't know what the stain is, except for ink. (Unfortunately, the harder we work on it, the color of the leather may change." And, he told me, if the stain turns yellow, those gloves will need to be refinished.

Fortunately, I sent my gloves there before any yellow stains could occur, so for upcoming Carnival season my gloves are now in tip-top shape.

|

Joseph Gershon came to America from Poland thru Ellis Island. The young man fostered a strong reputation in Kansas City, MO, for his exceptional skills with needle and thread. He opened Arrow’s doors in 1914 just a few blocks down on Troost from where the company is currently located. He planned to call his business “Gershon Tailors” but his cousin, a haberdasher, suggested “Arrow” like the popular shirts that he sold during that time. Now, 100 years later, the name is still a perfect match for its current owner, Bruce Gershon, the third generation of his family to helm the business.

Joseph married and raised a family in the Kansas City metro. His children attended Westport high school. Through the 20’s and 30’s, Joseph’s business continued to succeed. He gathered a strong, loyal customer following. Joseph’s son Melvin worked alongside his father, and then Bob Gershon returned from World War II in 1947 where he had been serving in the Air Force as a flight engineer on B-29’s, and began working immediately at the family business. It was around that time that Joseph decided to add to Arrow’s capabilities and brought dry cleaning in-house. click link to read more http://www.greenearthcleaning.com/news/185662/Arrow-Fabricare-Celebrates-100-years-.htm |

KC Business Magazine Top Companies of Kansas City 2014 - Arrow received " The Phoenix" Award

|

Download Here

| |||||||

Regis and Kelly and Joy's Jacket

Award of Excellence

|

The Drycleaning & Laundry Institute, which is the drycleaning industry's most influential trade association, published a most interesting article in it's December, 2009 magazine. The story relates Arrow's history and success as one of the most respected members of the association and also its recent achievement of earning the Institute's highest level of industry certification. Arrow is one of just a few drycleaners in America to reach this pinnacle of recognition

| |||||||

Arrow Cleaners:

Where You Bring Your Ink-Stained Cashmere Coat

by: Debbie Coleman-Topi

Published 07/09/2009 - 11:28 p.m. CDT

Email: content@kctribune.com

Credit: Michael McClure

Gayle Alexander, a seamstress with 28 years experience in the leather department, works on a colorful jacket sent from a client in California. Arrow frequently receives garments from around the world as well as flashy show business costumes from stars of stage and screen.

Arrow Cleaners proudly boasts they're the only dry cleaners in the area to work with designer Ralph Lauren, creator of the popular Polo line. Like many local dry cleaners, the Gershon business is family-owned and operated. But similarities to the typical mom-and-pop corner dry cleaners seem to stop there.

The differences especially are pronounced when considering Arrow's relationship with the popular Lauren designer label, which boasts product sales worldwide. Arrow once participated in a year-long project in which they helped the Ralph Lauren enterprise launch a new clothing line, featuring vintage-looking clothing including denim and leathers. Arrow processed 475,000 units of stone-washed denim and treated 20,000 pieces of leather from boots to belts and jackets, Bruce Gershon said.

"It literally turned my business upside down for over a year," Gershon said. During the project, Arrow transformed to a 24-hour operation, devoting much of its staff and space to the art of creating clothes with a yellowish, dingy tinge. The cleaners was credited with devising a chemical formula that not only looked old, but also wouldn't wash out during cleaning.

Arrow occupies 26,000 square feet in a melding of both old and new buildings and a parking lot that spans most of the block at 39th and Troost in Midtown. The plant features sections specializing in different types of cleaning. Hundreds of long clothing racks are intertwined in the areas. One area is devoted to dry cleaning normal clothing such as men's dress shirts and suits and women's blouses and slacks. Some pressing is done using a hand-held iron that shoots steam onto the garments. The dress shirts are pressed while hanging on a life-size bust.

Another area is devoted to wedding dresses, one of the business's specialties. In that area, operators are busy wrapping dresses in special air-tight boxes when the cleaning process is complete. Seamstresses perform mending and alterations, including re-knitting and re-weaving, while seated at sewing machines in another area. Yet another room is temperature-controlled and stores furs for customers out-of-season. The room is kept dark and at a constant 55 degrees, with 45 percent humidity for maximum preservation.

Industrial-sized machines that resemble large washing machines are scattered throughout the facility. One such machine uses an environmentally safe process called GreenEarth®, which was developed in Kansas City and uses silicone technology to clean leathers and textiles. Other machines include large tanks resembling home water heaters, which are used to capture the waste heat generated from the dry-cleaning process and heat the water used in the washing process.

The family-owned business differs from most area dry cleaners in yet another respect. The Gershons, which include owner/operator Bruce, his wife, Stephanie, his sister, Susie Shatz, and their father Bob, are joined by 70 employees, not members of the family.

Bruce Gershon knows his business is unique among dry cleaners.

This industry is the type of industry that if you have the right piece of equipment, you can hang out a sign," he said. "There are no industry-wide accreditation programs in our business", said Gershon. "Any basically-untrained person can begin a dry cleaners. And unfortunately some do."

"We're not a do-it-quick, do-it-cheap dry cleaner," he said. "We're a do-it-right dry cleaner."

Framed awards and other recognition hang in a neat row along one wall of Arrow's lobby, as if a testament to the company's high standards and longevity. Awards range from one for community service, which honors the company's volunteer cleaning of donated coats during an annual coat drive for area school children. Others are awards recognizing professionalism in several different cleaning techniques.

Arrow differs from most other Kansas City dry cleaners in that most of the cleaner's customers aren't just from the neighborhood. Instead, many hail from Johnson County and throughout greater Kansas City. But the business offers free pick-up and delivery, so customers aren't required to make the drive to the midtown office. Arrow does a huge mail-order and computer-order business, in which they ship out 40 to 60 boxes of orders per day. Orders hanging on a rack, earlier this week, came from as far away as Hawaii and Switzerland.

Bruce said one of the family's main goals has been to work to grow the business throughout the years, especially after he took over for his father, Bob Gershon, during the mid-1970s. Part of the growth came in the form of acquisitions and more employees, stemming from increased individual and commercial business. Another aspect of growth involved keeping current with changes in technology,in part by investing in modern equipment and several computer systems that keep the machines running properly and track their work. The business began relying on computers during the late 1980s and has installed several upgrades and new components throughout the years, Bruce said.

One such computer scans a small, permanent bar code that's placed within the inseam of all items that Arrow dry cleans. The code is so small that most customers are unaware of its existence, Bruce said. Once scanned, the bar code, instantly recalls the history of the piece being dry cleaned, providing its age, number of times cleaned there, repairs and other such information.

Arrow uses a mix of chemical solutions, each specifically designed to remove certain stains, including, blood, ink and coffee. The cleaners has stain removal specialists who are professionally trained in the procedures, Bob Gershon said.

"You really have to know your chemistry when treating stains," he said, adding that treatments partly depend on whether a stain is solvent-soluble or water-soluble.

Most Kansas Citians probably don't realize that when they send a leather coat, jacket, purse or other garment to any cleaners in the area, it probably ends up at Arrow, he said. His business is the area expert in cleaning such fabrics and even has the technology to re-dye faded or discolored leather. Arrow can clean large pieces of leather, as well. For instance, a rack of leather goods to be cleaned even included a set of leather couch covers.

Bob Gershon, Bruce's father, came into the business with his father, Joseph Gershon, about 1945, soon after Bob returned from World War II. Joseph, a Polish immigrant, learned the trade of tailor in the old country before moving to the states and opening a shop at 43rd and Troost, near the present location.

Bob, who works only a couple of hours most days, jokes that the business is very successful despite his absence. "It makes me sick...they're doing so good without me."

When asked what his grandfather would think of the business today, especially the growth and technology, Bruce could only reply: "My grandfather wouldn't have any clue."

Where You Bring Your Ink-Stained Cashmere Coat

by: Debbie Coleman-Topi

Published 07/09/2009 - 11:28 p.m. CDT

Email: content@kctribune.com

Credit: Michael McClure

Gayle Alexander, a seamstress with 28 years experience in the leather department, works on a colorful jacket sent from a client in California. Arrow frequently receives garments from around the world as well as flashy show business costumes from stars of stage and screen.

Arrow Cleaners proudly boasts they're the only dry cleaners in the area to work with designer Ralph Lauren, creator of the popular Polo line. Like many local dry cleaners, the Gershon business is family-owned and operated. But similarities to the typical mom-and-pop corner dry cleaners seem to stop there.

The differences especially are pronounced when considering Arrow's relationship with the popular Lauren designer label, which boasts product sales worldwide. Arrow once participated in a year-long project in which they helped the Ralph Lauren enterprise launch a new clothing line, featuring vintage-looking clothing including denim and leathers. Arrow processed 475,000 units of stone-washed denim and treated 20,000 pieces of leather from boots to belts and jackets, Bruce Gershon said.

"It literally turned my business upside down for over a year," Gershon said. During the project, Arrow transformed to a 24-hour operation, devoting much of its staff and space to the art of creating clothes with a yellowish, dingy tinge. The cleaners was credited with devising a chemical formula that not only looked old, but also wouldn't wash out during cleaning.

Arrow occupies 26,000 square feet in a melding of both old and new buildings and a parking lot that spans most of the block at 39th and Troost in Midtown. The plant features sections specializing in different types of cleaning. Hundreds of long clothing racks are intertwined in the areas. One area is devoted to dry cleaning normal clothing such as men's dress shirts and suits and women's blouses and slacks. Some pressing is done using a hand-held iron that shoots steam onto the garments. The dress shirts are pressed while hanging on a life-size bust.

Another area is devoted to wedding dresses, one of the business's specialties. In that area, operators are busy wrapping dresses in special air-tight boxes when the cleaning process is complete. Seamstresses perform mending and alterations, including re-knitting and re-weaving, while seated at sewing machines in another area. Yet another room is temperature-controlled and stores furs for customers out-of-season. The room is kept dark and at a constant 55 degrees, with 45 percent humidity for maximum preservation.

Industrial-sized machines that resemble large washing machines are scattered throughout the facility. One such machine uses an environmentally safe process called GreenEarth®, which was developed in Kansas City and uses silicone technology to clean leathers and textiles. Other machines include large tanks resembling home water heaters, which are used to capture the waste heat generated from the dry-cleaning process and heat the water used in the washing process.

The family-owned business differs from most area dry cleaners in yet another respect. The Gershons, which include owner/operator Bruce, his wife, Stephanie, his sister, Susie Shatz, and their father Bob, are joined by 70 employees, not members of the family.

Bruce Gershon knows his business is unique among dry cleaners.

This industry is the type of industry that if you have the right piece of equipment, you can hang out a sign," he said. "There are no industry-wide accreditation programs in our business", said Gershon. "Any basically-untrained person can begin a dry cleaners. And unfortunately some do."

"We're not a do-it-quick, do-it-cheap dry cleaner," he said. "We're a do-it-right dry cleaner."

Framed awards and other recognition hang in a neat row along one wall of Arrow's lobby, as if a testament to the company's high standards and longevity. Awards range from one for community service, which honors the company's volunteer cleaning of donated coats during an annual coat drive for area school children. Others are awards recognizing professionalism in several different cleaning techniques.

Arrow differs from most other Kansas City dry cleaners in that most of the cleaner's customers aren't just from the neighborhood. Instead, many hail from Johnson County and throughout greater Kansas City. But the business offers free pick-up and delivery, so customers aren't required to make the drive to the midtown office. Arrow does a huge mail-order and computer-order business, in which they ship out 40 to 60 boxes of orders per day. Orders hanging on a rack, earlier this week, came from as far away as Hawaii and Switzerland.

Bruce said one of the family's main goals has been to work to grow the business throughout the years, especially after he took over for his father, Bob Gershon, during the mid-1970s. Part of the growth came in the form of acquisitions and more employees, stemming from increased individual and commercial business. Another aspect of growth involved keeping current with changes in technology,in part by investing in modern equipment and several computer systems that keep the machines running properly and track their work. The business began relying on computers during the late 1980s and has installed several upgrades and new components throughout the years, Bruce said.

One such computer scans a small, permanent bar code that's placed within the inseam of all items that Arrow dry cleans. The code is so small that most customers are unaware of its existence, Bruce said. Once scanned, the bar code, instantly recalls the history of the piece being dry cleaned, providing its age, number of times cleaned there, repairs and other such information.

Arrow uses a mix of chemical solutions, each specifically designed to remove certain stains, including, blood, ink and coffee. The cleaners has stain removal specialists who are professionally trained in the procedures, Bob Gershon said.

"You really have to know your chemistry when treating stains," he said, adding that treatments partly depend on whether a stain is solvent-soluble or water-soluble.

Most Kansas Citians probably don't realize that when they send a leather coat, jacket, purse or other garment to any cleaners in the area, it probably ends up at Arrow, he said. His business is the area expert in cleaning such fabrics and even has the technology to re-dye faded or discolored leather. Arrow can clean large pieces of leather, as well. For instance, a rack of leather goods to be cleaned even included a set of leather couch covers.

Bob Gershon, Bruce's father, came into the business with his father, Joseph Gershon, about 1945, soon after Bob returned from World War II. Joseph, a Polish immigrant, learned the trade of tailor in the old country before moving to the states and opening a shop at 43rd and Troost, near the present location.

Bob, who works only a couple of hours most days, jokes that the business is very successful despite his absence. "It makes me sick...they're doing so good without me."

When asked what his grandfather would think of the business today, especially the growth and technology, Bruce could only reply: "My grandfather wouldn't have any clue."

The Independent Magazine, Feb. 2, 2008 (p.15)

Kansas City Comes Through Again

Kansas City came through again when nearly 11,000 coats were distributed during the 2007 Coats for Kids campaign. After weeks of collection and dry cleaning, the coats were distributed to the Kansas City Missouri, Kansas City Kansas, Independence, and Hickman Mills School Districts. From there, the administrators and teachers distributed the coats to the children.

The major sponsors of this year's NewsRadio 980 KMBZ Coats for Kids campaign were Arrow Fabricare Services, Pride Cleaners, Sertoma Club of Kansas City, U.S. Army Recruiting Battalion, Kansas City Missouri office; and KMBZ employees. Supporting this year's campaign were Gail's Harley Davidson, The Mortgage Store, O'Reilly Auto Parts, Blue Cross Blue Shield and Carrabba's Italian Grill.

A total of $16,005 was contributed by many individuals and companies in our community. All of the money collected was used to purchase new coats for the children. Over the five years of the campaign, a total of 38,577 coats have been collected and given out. Kansas City has truly risen to the occasion of keeping the children of Our Town warm in the winter. A clean, previously worn or brand new coat reached Kansas City kids just in time for winter, thanks to many of you.

Kansas City Comes Through Again

Kansas City came through again when nearly 11,000 coats were distributed during the 2007 Coats for Kids campaign. After weeks of collection and dry cleaning, the coats were distributed to the Kansas City Missouri, Kansas City Kansas, Independence, and Hickman Mills School Districts. From there, the administrators and teachers distributed the coats to the children.

The major sponsors of this year's NewsRadio 980 KMBZ Coats for Kids campaign were Arrow Fabricare Services, Pride Cleaners, Sertoma Club of Kansas City, U.S. Army Recruiting Battalion, Kansas City Missouri office; and KMBZ employees. Supporting this year's campaign were Gail's Harley Davidson, The Mortgage Store, O'Reilly Auto Parts, Blue Cross Blue Shield and Carrabba's Italian Grill.

A total of $16,005 was contributed by many individuals and companies in our community. All of the money collected was used to purchase new coats for the children. Over the five years of the campaign, a total of 38,577 coats have been collected and given out. Kansas City has truly risen to the occasion of keeping the children of Our Town warm in the winter. A clean, previously worn or brand new coat reached Kansas City kids just in time for winter, thanks to many of you.

American Drycleaner, February 2008 (p.142)

Coats for Kids Clothes 11,000 in Kansas City

A Kansas City Coats for Kids campaign spearheaded by NewsRadio 980 KMBZ distributed almost 11,000 coats last month to area children in need of warm winter garments.

After weeks of collecting and cleaning the coats, sponsors distributed them to four metro-area school districts. Administrators and teachers then distributed the coats to children.

Arrow Fabricare Services and Pride Cleaners donated drycleaning services to the effort. Additional supporters included Missouri's U.S. Army recruiting Battalion, Blue Cross/Blue Shield and several local businesses.

The campaign also received $16,005 in monetary donations, which was used to purchase new coats. In five years, the area's Coats for Kids campaign has collected, cleaned and distributed 38,577 coats to needy children.

Coats for Kids Clothes 11,000 in Kansas City

A Kansas City Coats for Kids campaign spearheaded by NewsRadio 980 KMBZ distributed almost 11,000 coats last month to area children in need of warm winter garments.

After weeks of collecting and cleaning the coats, sponsors distributed them to four metro-area school districts. Administrators and teachers then distributed the coats to children.

Arrow Fabricare Services and Pride Cleaners donated drycleaning services to the effort. Additional supporters included Missouri's U.S. Army recruiting Battalion, Blue Cross/Blue Shield and several local businesses.

The campaign also received $16,005 in monetary donations, which was used to purchase new coats. In five years, the area's Coats for Kids campaign has collected, cleaned and distributed 38,577 coats to needy children.

Arrow's Gershon Earns Three DLI Certifications

Bruce Gershon, president of Arrow Fabricare Services in Kansas City, has earned all three certifications that the Drycleaning & Laundry Institute (DLI) offers - Certified Environmental Drycleaner (CED), Certified Professional Drycleaner (CPD) and Certified Professional Wetcleaner (CPW)

Operators who earn all three are named Certified Garment Care Professionals (CGCPs). To achieve this status, they must master a comprehensive body of knowledge of professional drycleaning, and pass 12 hours of written examinations to verify their expertise.

"Several new processes are changing the drycleaning business, and the driving force is environmentalism - the effort to use gentler methods to clean clothes," Gershon says. "I like to push the envelope. If my knowledge is tested, employees respect that. I expect a higher level of commitment from each of the Arrow employees."

Gershon entered the industry in the '70s as Arrow's third-generation owner. He was the first midwestern drycleaner to earn DLI's Award of Excellence.

Bruce Gershon, president of Arrow Fabricare Services in Kansas City, has earned all three certifications that the Drycleaning & Laundry Institute (DLI) offers - Certified Environmental Drycleaner (CED), Certified Professional Drycleaner (CPD) and Certified Professional Wetcleaner (CPW)

Operators who earn all three are named Certified Garment Care Professionals (CGCPs). To achieve this status, they must master a comprehensive body of knowledge of professional drycleaning, and pass 12 hours of written examinations to verify their expertise.

"Several new processes are changing the drycleaning business, and the driving force is environmentalism - the effort to use gentler methods to clean clothes," Gershon says. "I like to push the envelope. If my knowledge is tested, employees respect that. I expect a higher level of commitment from each of the Arrow employees."

Gershon entered the industry in the '70s as Arrow's third-generation owner. He was the first midwestern drycleaner to earn DLI's Award of Excellence.

Awash in luxury

At Blanc Plume in KC, sheets and table cloths get special, hands-on treatment.

By Stacy Downs

The Kansas City Star

Photos by John Mutrux | The Kansas City Star

Blanc Plume employee Susana Martinez uses a 7-foot press to smooth a damp bedsheet in one step. Some laundry services instead use a mangle, a heated-roller machine that smoothes fabric. A mangle can leave slight creases around the edges.

The large "stretching frame" assures that coverlets are returned to the customer at their original size and do not shrink. Shrinkage is a large problems when hi-end bedding is processed by a dry cleaner who does not specialize in the work.

There are only a handful of French laundries in the United States, and Kansas City can boast having one of them - Blanc Plume in North Kansas City.

Richard Triggs of Kansas City takes his Egyptian cotton sheets to Blanc Plume ("white feather") to be laundered a few times a month. "It's kind of a treat," he said. "It feels like you're sleeping on brand-new sheets again."

French laundries specialize in luxury linens such as bedding made of Egyptian cotton, merino wool, pure linen, cashmere or silk.

They also clean intricately decorated pieces such as pillows beaded with crystals. These laundries are where you'd take heirloom pieces (Grandma's embroidered tablecloth) but not necessarily bedding from a discount retailer.

At a French laundry, stains are individually pretreated with a mild solution before being washed. Linens are pressed damp to ensure a crisp finish.

Special attention is paid to details. For example, tassels and fringe are bundled or braided before laundering to prevent balling or knotting, says Connie Mosier, general manager of Blanc Plume, a division of Arrow Fabricare. After laundering, the fringe is finger combed.

Luxury linen companies such as Anichini, DeWoolfson, Duxiana, Peacock Alley and Yves Delorme recommend that their products be laundered at Blanc Plume. "They're the best," said Alan Jesseman, creative director for Anichini, a Vermont company that uses handcrafted fabrics from Lithuania and Italy to make bedding for boutiques and hotels.

Blanc Plume employees have expertise that goes beyond a traditional dry cleaner or laundry service, Jesseman said.

Anichini customers receive a packet of information about Blanc Plume and a shipping label. Blanc Plume receives linens for laundering from across the country.

Linen store owners also recommend Blanc Plume for restoration. Ursula Terrasi, owner of Scandia Down on the Country Club Plaza, said a customer once brought in a matelasse coverlet that had been machine laundered at home. It shrunk, was wrinkled and no longer fit the bed. "They took it to Blanc Plume and when it was returned, it was like nothing had happened," Terrasi said.

Matelassé is a triple-woven cotton jacquard fabric with raised patterning that requires professional laundering. It naturally shrinks up to 10 percent when it's washed. Blanc Plume measures the coverlet and uses a blocking process to retain the original size.

The blocking process also is used to stretch lace tablecloths and bedskirts that have high-quality skirting fabric but inexpensive decking material that makes them hang improperly.

Blanc Plume also specializes in down comforter and pillow restoration. Down products should be professionally cleaned every other year to help redistribute the down. The company can add additional down and replace the ticking, or outer shell, if needed. The "down room" is enclosed with a screened door so the lightweight fluffy stuff doesn't float throughout the facility at 1333 Washington Blvd..

Patsy Thomas of Kansas City takes her down products, needlepoint chair cushions and tablecloths to Blanc Plume. She likes how comforters come back wrapped in heavy plastic zippered bags. Tablecloths are returned rolled or folded precisely with acid-free tissue paper.

"When I take my tablecloths out for the next holiday, they look done up to perfection," Thomas said. "It (Blanc Plume) is a great secret source to have in town."

At Blanc Plume in KC, sheets and table cloths get special, hands-on treatment.

By Stacy Downs

The Kansas City Star

Photos by John Mutrux | The Kansas City Star

Blanc Plume employee Susana Martinez uses a 7-foot press to smooth a damp bedsheet in one step. Some laundry services instead use a mangle, a heated-roller machine that smoothes fabric. A mangle can leave slight creases around the edges.

The large "stretching frame" assures that coverlets are returned to the customer at their original size and do not shrink. Shrinkage is a large problems when hi-end bedding is processed by a dry cleaner who does not specialize in the work.

There are only a handful of French laundries in the United States, and Kansas City can boast having one of them - Blanc Plume in North Kansas City.

Richard Triggs of Kansas City takes his Egyptian cotton sheets to Blanc Plume ("white feather") to be laundered a few times a month. "It's kind of a treat," he said. "It feels like you're sleeping on brand-new sheets again."

French laundries specialize in luxury linens such as bedding made of Egyptian cotton, merino wool, pure linen, cashmere or silk.

They also clean intricately decorated pieces such as pillows beaded with crystals. These laundries are where you'd take heirloom pieces (Grandma's embroidered tablecloth) but not necessarily bedding from a discount retailer.

At a French laundry, stains are individually pretreated with a mild solution before being washed. Linens are pressed damp to ensure a crisp finish.

Special attention is paid to details. For example, tassels and fringe are bundled or braided before laundering to prevent balling or knotting, says Connie Mosier, general manager of Blanc Plume, a division of Arrow Fabricare. After laundering, the fringe is finger combed.

Luxury linen companies such as Anichini, DeWoolfson, Duxiana, Peacock Alley and Yves Delorme recommend that their products be laundered at Blanc Plume. "They're the best," said Alan Jesseman, creative director for Anichini, a Vermont company that uses handcrafted fabrics from Lithuania and Italy to make bedding for boutiques and hotels.

Blanc Plume employees have expertise that goes beyond a traditional dry cleaner or laundry service, Jesseman said.

Anichini customers receive a packet of information about Blanc Plume and a shipping label. Blanc Plume receives linens for laundering from across the country.

Linen store owners also recommend Blanc Plume for restoration. Ursula Terrasi, owner of Scandia Down on the Country Club Plaza, said a customer once brought in a matelasse coverlet that had been machine laundered at home. It shrunk, was wrinkled and no longer fit the bed. "They took it to Blanc Plume and when it was returned, it was like nothing had happened," Terrasi said.

Matelassé is a triple-woven cotton jacquard fabric with raised patterning that requires professional laundering. It naturally shrinks up to 10 percent when it's washed. Blanc Plume measures the coverlet and uses a blocking process to retain the original size.

The blocking process also is used to stretch lace tablecloths and bedskirts that have high-quality skirting fabric but inexpensive decking material that makes them hang improperly.

Blanc Plume also specializes in down comforter and pillow restoration. Down products should be professionally cleaned every other year to help redistribute the down. The company can add additional down and replace the ticking, or outer shell, if needed. The "down room" is enclosed with a screened door so the lightweight fluffy stuff doesn't float throughout the facility at 1333 Washington Blvd..

Patsy Thomas of Kansas City takes her down products, needlepoint chair cushions and tablecloths to Blanc Plume. She likes how comforters come back wrapped in heavy plastic zippered bags. Tablecloths are returned rolled or folded precisely with acid-free tissue paper.

"When I take my tablecloths out for the next holiday, they look done up to perfection," Thomas said. "It (Blanc Plume) is a great secret source to have in town."

|

National Clothesline a leading industry trade newspaper, published a very nice story on Bruce Gershon, President of Arrow Fabricare Services.

| |||||||

American Drycleaner, January 2005, (pp. 46-48)

Special Honors for Best Renovation Design

Located in urban Kansas City, Mo., for more than 90 years, Arrow Fabricare Services has watched the market for its unique blend of retail and specialty services shift to the suburbs over the years. But even after following the business with a vast route network and wholesale business, Arrow never gave up on its venerable processing facility.

Arrow has renovated the plant to streamline internal processes three times in the last 15 years. But this time, owner Bruce Gershon made a concerted effort to acquire adjacent properties and expanded the plant 6,300 sq. ft. with an addition built to match the original building's brick and mortar construction. Arrow now occupies 20,000 sq. ft. at this plant alone.

"It's making a world of difference," Gershon says. "We've been in a cramped space here for a couple of years while we've moved forward with the plans to expand. I have to acknowledge the commitment and customer-focused dedication of the Arrow employees who have maintained smooth workflow in somewhat difficult circumstances."

In addition to drycleaning, shirt laundry and alterations, Arrow offers pillow and bedding care, leather and suede service, fur cleaning and storage, gown preservation and cleaning, and fire gear cleaning and repair. A second, 10,300 sq. ft. plant in North Kansas City houses high-end sister business Blanc Plume and Arrow's fire restoration operations.

Mainly a production facility, the plant was remapped to enhance its capabilities. Contractors moved and re-installed 54 pieces of equipment and installed 14 new machines, including a Union GreenEarth machine, dedicated to leather cleaning, two Omega reclaimers, a 30 HP Hurst boiler, a Hamilton hot water tank and a new screw compressor.

Existing equipment included a Bruske tensioning pant unit, UniMac washers, ADC and Cissell dryers, Unipress doublebuck shirt units and a variety of traditional pressing equipment from Ajax, Cissell, Forenta and Hoffman/NewYorker. The addition helped integrate all of this machinery into lines covering drycleaning, shirts, and leathers and furs, as well as dedicated new space to gown preservation, fur storage and wholesale shipping.

On the other end of the plant, walk-in customers benefit from a renovated corner entrance with lighted awnings and brand-new horseshoe countertops from R.J. Papalini. Immediately behind the counters, a plasma screen shows Arrow's wide range of services. And behind that, a new "cubby" unit helps hide bulky items, such as comforters, and screens the factory floor from view. A recessed DCCS point-of-sale (POS) system manages the counter, mark-in and workflow.

Part of Arrow's reasoning in staying at its downtown location was to keep its loyal, long-term employees, and the facility employs more than 60. But the operation went one step further, adding climate control, a new employee parking lot and an expanded break room.

Arrow continues to grow by following the money and tapping new categories of customers such as garment manufacturers and retailers. But it has been able to do so by holding onto its roots and letting the operation blossom from there.

Special Honors for Best Renovation Design

Located in urban Kansas City, Mo., for more than 90 years, Arrow Fabricare Services has watched the market for its unique blend of retail and specialty services shift to the suburbs over the years. But even after following the business with a vast route network and wholesale business, Arrow never gave up on its venerable processing facility.

Arrow has renovated the plant to streamline internal processes three times in the last 15 years. But this time, owner Bruce Gershon made a concerted effort to acquire adjacent properties and expanded the plant 6,300 sq. ft. with an addition built to match the original building's brick and mortar construction. Arrow now occupies 20,000 sq. ft. at this plant alone.

"It's making a world of difference," Gershon says. "We've been in a cramped space here for a couple of years while we've moved forward with the plans to expand. I have to acknowledge the commitment and customer-focused dedication of the Arrow employees who have maintained smooth workflow in somewhat difficult circumstances."

In addition to drycleaning, shirt laundry and alterations, Arrow offers pillow and bedding care, leather and suede service, fur cleaning and storage, gown preservation and cleaning, and fire gear cleaning and repair. A second, 10,300 sq. ft. plant in North Kansas City houses high-end sister business Blanc Plume and Arrow's fire restoration operations.

Mainly a production facility, the plant was remapped to enhance its capabilities. Contractors moved and re-installed 54 pieces of equipment and installed 14 new machines, including a Union GreenEarth machine, dedicated to leather cleaning, two Omega reclaimers, a 30 HP Hurst boiler, a Hamilton hot water tank and a new screw compressor.

Existing equipment included a Bruske tensioning pant unit, UniMac washers, ADC and Cissell dryers, Unipress doublebuck shirt units and a variety of traditional pressing equipment from Ajax, Cissell, Forenta and Hoffman/NewYorker. The addition helped integrate all of this machinery into lines covering drycleaning, shirts, and leathers and furs, as well as dedicated new space to gown preservation, fur storage and wholesale shipping.

On the other end of the plant, walk-in customers benefit from a renovated corner entrance with lighted awnings and brand-new horseshoe countertops from R.J. Papalini. Immediately behind the counters, a plasma screen shows Arrow's wide range of services. And behind that, a new "cubby" unit helps hide bulky items, such as comforters, and screens the factory floor from view. A recessed DCCS point-of-sale (POS) system manages the counter, mark-in and workflow.

Part of Arrow's reasoning in staying at its downtown location was to keep its loyal, long-term employees, and the facility employs more than 60. But the operation went one step further, adding climate control, a new employee parking lot and an expanded break room.

Arrow continues to grow by following the money and tapping new categories of customers such as garment manufacturers and retailers. But it has been able to do so by holding onto its roots and letting the operation blossom from there.

|

January 2005

Kansas City Mayor Pro-term Alvin Brooks presents a city

proclamation recognizing Arrow Fabricare’s 90 years of work in the city. From left: Bob Gershon, Alvin Brooks, Bruce Gershon, president. |

Arrow Fabricare Services recently celebrated 90 years in

Kansas City, Missouri, and for the third time in recent years, Arrow has remodeled and expanded. The expansion adds 6,300 square feet to the existing plant and houses a refrigerated fur storage vault, an expanded leather and fur cleaning and repair area, a new shipping and receiving area, and a new truck dock. The new addition allowed for doubling and upgrading the employee break room and meeting space. A diversified, third-generation family-owned business, Arrow provides regular and specialty dry cleaning and laundry services. Arrow Leathercare is nationally known and recommended by nearly 100 manufacturers for wholesale and retail leather cleaning and dyeing, as well as fur and leather repair services via mail order. “This business is proof that American free enterprise is the best method to build value,” Arrow President Bruce Gershon said. “Ninety years ago, my grandfather couldn’t have dreamed a dream this big.” |

NY TIMES runs a feature on Blanc Plume, Arrow's Fine French Laundry

On November 15, 2001, the New York Times featured Blanc Plume, Arrow's fine french laundry with a complimentary and information featurette in their "Inside Sources" section of the paper. Much new business resulted as a huge readership was acquainted with Arrow's superb standards of quality and services...particularly for fine, high-quality bedding, down pillows and comforters and fine and heirloom linen.