| 2011_arrowtoday_1stqtr.pdf |

|

0 Comments

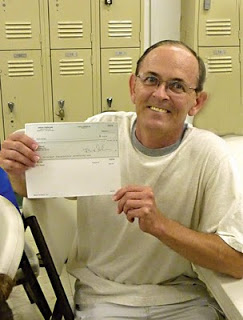

From Bruce Gershon, CEO of Arrow. "In my ever continuing effort to go green, while at the same time paying attention to Arrow's bottom line, I recently filled out a survey from my friends a Western Extralite. In this survey, I learned about ways to properly dispose of and re-cycle spent florescent tubes, and that there were programs available to take advantage of rebates from KCP&L, if we were to consider upgrading the lighting in our buildings. "As I began to research the different lighting options, I learned that we could really improve the overall quality of our lighting, and at the same time save energy. Western Extralite, the electrical contractor and I walked our entire facility, we discussed my goals and priorities, the new lighting fixture options, and how they would improve the quality of our lighting. The next step was to contract for a thorough scientific evaluation of the lighting in our facility. Western, together with the contractor, KC One Service Company, crunched the numbers and prepared a proposal with three different options for the project. The first option was clearly the winner; in fact it was a “no brainer”. It called for replacing nearly every light fixture with new energy efficient fixtures that would provide better, more consistent lighting, at less than half of the energy cost. "Another amazing thing that came of the study was that by using this new technology, we would end up with over 100 fewer fixtures, which would also save on the installation costs for the project. We then submitted our application to KCP&L for the rebate, signed off on the proposal, and materials were ordered. "The project is now 100% complete, and the results are amazing, there is a day and night difference. The newly lit areas look brighter and cleaner and the staff even seems more cheerful! The investment was significant, but after the KCP&L rebate, along with the projected energy savings, it pencils out to a two year return on investment….what a deal! We get greener, brighter, cleaner, happier, and save money to boot!"  Danny Stewart, a plant employee, recently became the first winner of Arrow’s new “Creative Suggestions” recognition incentive program. He also won a $600.00 bonus for his idea. With his suggestion for modifying the method of shutting down the boilers at night, Danny showed how employees can positively affect the bottom line at Arrow. His suggestion will save Arrow several thousand dollars per year in utility costs and also positively affect the conditions in the plant for his fellow workers. CONGRATULATIONS TO DANNY FOR HIS INGENUITY AND CREATIVITY!  Arrow Fabricare has introduced Arrow GreenCare, a customer-care program addressing the community's request for environmentally-friendly methods of dry cleaning. Dry Cleaning Alternatives Fortunately, the dry cleaning industry has evolved sufficiently that we can now offer the public two fine alternatives to using "perc" or other harsh chemicals to clean their clothing. Any customer requesting green dry cleaning can be assured that their garments will be processed in either GreenEarth ™ siloxane solution or in Arrow's professional wet cleaning solution, using water as the primary solvent, with earth-friendly surfactants doing the soil extraction in sophisticated, computer-controlled machines. These special wetcare machines are designed to extract deeper soils while agitation and abrasion are kept to a minimum. Voluntary and Mandated Emission Controls Even before EPA rulings of the 1980's, Arrow regulated its liquid emissions by preventing any harmful runoff into sanitary sewers or surrounding land. We accomplished this with containment pans under any equipment that "might" be responsible for any solvent spill or leak. When the technology became available and advanced enough, we installed a soil vapor extraction system to provide additional monitoring. We use a specially-licensed recycler for disposal of potential contaminants such as still residue and left-over dyes that cannot be recycled onsite. Degrading "The Plastic Bags" While polyfilm coverings keep customers' clothing tidy and clean during transport, the polyfilm industry is only now beginning to recognize the need to reduce or eliminate the non-degradable film from landfills around the globe. Arrow is proactively offering degradable polyfilm coverings on Arrow GreenCare orders. The new films are designed to degrade into an earth-friendly dust or flakes within two years. We advise customers to remove the bags before storing their items long-term in closets or drawers because the degradation process will begin in approximately two years. Re-Cycling Through Re-Use In an effort to further protect your garments, Arrow introduced the re-usable Arrow GreenCare transport bag. It serves a dual purpose, depending upon its configuration. It is convertible as a convenient bag for transporting your clothing TO Arrow. When your garments are clean, the GreenCare bag converts to a covering for your clothes FROM Arrow! Hangers Away! If you are among the many who find wire hangers collecting on the closet floor or in piles destined for the trash, Arrow will take them in and recycle them. If bagged, we will accept them at our counter location on Troost. We will pick them up from our residential route customers if they are bagged separately from the clothing and marked for pickup. Arrow is working with the Kansas City Rehabilitation Institute to send wire hangers to for a planned recycling program. www.rehabkc.org Other Ways Arrow Targets"Greening" Over the past few years, Arrow has trimmed electrical usage by managing electrical shut-offs in the plant. We re-roofed the building with white, sun-reflective roofing material and installed roof-mounted evaporative coolers. The building has limited-area air conditioning, thermal-pane windows, energy-efficient overhead doors at our docks, and all lighting fixtures are using "low-e" replacement bulbs. A Growing Benefit: Eco-Affiliations Each new customer coming to Arrow's GreenCare program will be honored with an Arrow donation to the Heartland Tree Alliance. HTA is a resource for helping to manage the "urban and community forest" in conjunction with Bridging the Gap. Kansas City's economic benefit from its trees exceeds $51 million and arborists are encouraging even more planting. www.heartlandtreealliance.org Arrow is pleased to be part of the KCP&L "M-Power" initiative to manage future power needs while eliminating or postponing the construction of new generating plants. www.MPowerKansasCity.com Also, as a member of the Greater Kansas City Chamber of Commerce, Arrow has committed to serving on the Chamber's Committee on the Environment. www.kcchamber.com |

Arrow Fabricare

News and Information about Arrow Fabricare Services Archives

August 2020

Categories

All

|

RSS Feed

RSS Feed